Ipe Wood Panels A Comprehensive Guide

Ipe wood panels are a stunning choice for construction and design, boasting exceptional durability and aesthetic appeal. These panels, crafted from the strong and weather-resistant ipe wood, are prized for their ability to withstand harsh outdoor conditions while adding a sophisticated touch to any project. Their versatility extends from exterior applications to interior design, furniture, and cabinetry, making them a true all-rounder.

This guide delves into the intricacies of ipe wood panels, covering everything from their manufacturing processes and cost considerations to their sustainability credentials and installation procedures. We’ll explore the unique characteristics of ipe wood that make it such a desirable material, compare it to other popular options, and highlight the numerous applications where these panels truly shine.

Introduction to Ipe Wood Panels

Ipe wood panels are a popular choice for outdoor applications due to their exceptional durability and aesthetic qualities. Derived from the ipe hardwood tree, these panels offer a strong, attractive, and long-lasting solution for various construction and design projects. Their resistance to rot, decay, and insect infestation makes them particularly well-suited for demanding environments.

Ipe wood’s dense, strong structure, coupled with its natural resistance to moisture and weathering, results in a material that can endure harsh conditions for extended periods. This inherent resilience makes ipe wood panels an ideal choice for decking, cladding, fencing, and other exterior applications where longevity is paramount.

Key Characteristics of Ipe Wood

Ipe wood is renowned for its exceptional strength, density, and durability. Its natural resistance to moisture, rot, and insect damage sets it apart from other wood species, making it exceptionally suitable for outdoor use. The dense structure of ipe wood also contributes to its high impact resistance.

Common Dimensions and Sizes of Ipe Wood Panels

Ipe wood panels are typically available in various dimensions and sizes to suit diverse project needs. Standard panel sizes can range from 4 feet by 8 feet to 6 feet by 12 feet. Thicknesses commonly found in the market include 1.5 inches, 2 inches, and 3 inches, depending on the specific application and the desired level of structural support. Custom sizes are also available upon request, although these may incur additional costs.

Comparison of Ipe Wood Panels to Other Panel Materials

The following table compares ipe wood panels to other common panel materials, highlighting their respective strengths and weaknesses.

| Material | Durability | Cost | Maintenance | Sustainability | Appearance |

|---|---|---|---|---|---|

| Ipe Wood | Excellent; highly resistant to rot, decay, and insects | Moderate to High | Low: Minimal maintenance required | Moderate; requires responsible sourcing | Rich, dark brown; attractive grain |

| Oak | Good; susceptible to rot and insects | Moderate | Moderate; requires periodic sealing and treatment | Variable; depends on harvesting practices | Various shades of brown; attractive grain |

| Bamboo | Good; relatively resistant to rot and insects | Low to Moderate | Moderate; requires periodic cleaning | High: a fast-growing renewable resource | Striped; distinct appearance |

| Composite | Excellent; highly resistant to rot, decay, and insects | Moderate to High | Low: Minimal maintenance required | Variable; depends on the specific composite | Variety of colors and textures; may not match natural wood |

Note that the cost and sustainability ratings are relative and can vary based on factors like sourcing and processing methods. Ipe wood, while offering exceptional durability, has a higher price point compared to some alternatives, such as bamboo. The choice of material will ultimately depend on the specific project requirements and budget constraints.

Applications of Ipe Wood Panels

Source: timberblogger.com

Ipe wood panels, renowned for their exceptional durability and aesthetic appeal, find extensive use in a wide range of applications. Their resistance to rot, decay, and insect infestation makes them a premier choice for exterior projects, while their rich, warm tones complement various interior design styles. This section explores the versatility of ipe wood panels across construction, interior design, and furniture sectors.

Exterior Applications in Construction

Ipe wood panels excel in exterior applications due to their remarkable resistance to weathering. Their inherent durability makes them ideal for cladding, decking, and fencing. The natural beauty of ipe adds a touch of elegance and sophistication to any exterior project, while its resilience ensures longevity and minimal maintenance. For example, ipe decking can withstand heavy use and harsh weather conditions, offering years of enjoyment without significant upkeep. Furthermore, ipe panels can be used for creating visually striking and structurally sound exterior walls and siding.

Interior Design Applications

The rich color palette and natural beauty of ipe wood panels also make them a superb choice for interior design projects. The warm, inviting tones of ipe can create a sophisticated and luxurious ambiance. They are particularly well-suited for wall panelling, creating focal points, and adding depth to rooms. Ipe panels can also be used for creating custom cabinetry and shelving units, enhancing the overall aesthetic of the space. Consider a dining room with ipe wall panelling and matching cabinetry – the rich tones create a sense of warmth and elegance.

Furniture and Cabinetry Applications

Ipe wood’s exceptional strength and stability make it a premier material for furniture and cabinetry. The wood’s tight grain and dense structure lend themselves well to intricate designs and precise woodworking. Ipe furniture and cabinetry are not only durable but also highly aesthetically pleasing, showcasing the wood’s natural beauty. A custom-built ipe entertainment center, for instance, can provide both a practical and visually stunning storage solution for a living room. The wood’s inherent resistance to warping and cracking makes it ideal for pieces that experience frequent use.

Showcase Projects

Numerous projects showcase the beauty and durability of ipe wood panels. A notable example is the use of ipe decking on a beachfront home, where the panels successfully withstood years of exposure to salt spray and extreme weather conditions. Another project featuring ipe panels involved creating a stunning, modern home exterior. The ipe cladding not only enhanced the aesthetic appeal but also protected the structure from the elements.

Specific Uses Across Industries

| Industry | Specific Use |

|---|---|

| Residential Construction | Exterior cladding, decking, fencing, interior wall panelling, cabinetry |

| Commercial Construction | Exterior cladding, high-traffic flooring, interior accents |

| Furniture Manufacturing | Cabinets, tables, chairs, shelving units |

| Outdoor Recreation | Decking, picnic tables, benches |

Manufacturing Processes of Ipe Wood Panels

Source: coverdeck.com

Ipe wood, renowned for its exceptional strength and durability, necessitates meticulous manufacturing processes to maintain its quality and suitability for diverse applications. These processes, from initial milling to final finishing, play a crucial role in ensuring the longevity and aesthetic appeal of the finished panels. The methods employed also influence the environmental footprint of the manufacturing process.

The manufacturing of ipe wood panels involves a series of carefully controlled steps, each designed to preserve the wood’s inherent properties while shaping it into usable panels. This meticulous approach ensures the end product meets stringent quality standards, guaranteeing its suitability for a variety of applications, from exterior cladding to high-end furniture.

Typical Manufacturing Methods

The production of ipe wood panels typically involves several stages, starting with the initial harvesting and processing of the logs. These stages include milling, planing, and finishing. Each step plays a crucial role in achieving the desired final product.

- Milling: This initial stage involves transforming the raw ipe logs into lumber. Specialized machinery, such as band saws and planers, precisely cuts the logs into manageable planks. Careful attention to grain direction and minimizing waste is critical. This ensures that the resulting lumber is suitable for further processing and minimizes material loss. The milling process also creates a consistent surface for subsequent planing and finishing stages.

- Planing: Following milling, the lumber undergoes planing to achieve a uniform thickness and smooth surface. Planers utilize rotating blades to shave off excess wood, creating the desired dimensions and ensuring a consistent surface quality across the panels. Planning is essential for achieving the dimensional accuracy and smooth finish required for various applications.

- Finishing: The final stage often involves applying protective coatings, such as stains, sealers, or varnishes. These treatments not only enhance the aesthetic appeal of the ipe wood panels but also contribute to their longevity by providing a barrier against environmental factors like moisture and UV radiation. The type of finish selected depends on the intended use and desired aesthetic. For example, a clear sealant might be suitable for applications where the natural beauty of the wood is desired, while a pigmented stain might be chosen for aesthetic customization.

Quality Control Measures

Ensuring the quality of ipe wood panels is paramount. A robust quality control system is integral to maintaining the high standards associated with this exceptional wood.

- Dimensional Accuracy: Rigorous measurements are taken at each stage to ensure the panels meet the specified dimensions. Tolerances are meticulously monitored to maintain consistency. Variations in thickness, width, and length are closely scrutinized to ensure uniformity.

- Surface Quality: Visual inspections and specialized equipment are used to assess the surface smoothness and absence of defects like knots, cracks, or blemishes. Strict adherence to established standards is crucial.

- Moisture Content: The moisture content of the ipe wood is carefully monitored throughout the manufacturing process. This is essential because variations in moisture content can affect the dimensional stability and longevity of the finished panels.

Comparison of Manufacturing Processes

Different manufacturing processes can offer varying advantages and disadvantages. The selection of a particular process often depends on the specific application and desired outcome.

| Manufacturing Process | Strengths | Weaknesses |

|---|---|---|

| Traditional Sawing | Cost-effective for smaller production runs; skilled labor can create unique shapes and sizes. | Slower than modern methods; potential for greater waste; less consistent dimensions. |

| CNC Milling | Highly precise dimension, consistent quality, faster production, reduced waste. | Higher initial investment in equipment; may not be suitable for highly customized designs. |

Environmental Impact

The environmental impact of ipe wood panel manufacturing needs to be carefully considered. Sustainable practices are essential to minimize the ecological footprint of the process.

- Sustainable Sourcing: Prioritizing sustainably managed forests is crucial to ensure the long-term availability of ipe wood while minimizing deforestation. Certifications like Forest Stewardship Council (FSC) can help guarantee responsible harvesting.

- Minimizing Waste: Efficient use of lumber during milling and planing is crucial to reduce waste. Recycling or repurposing leftover materials can further minimize environmental impact.

- Energy Efficiency: Implementing energy-efficient equipment and practices can significantly reduce the carbon footprint of the manufacturing process. Renewable energy sources should be considered.

Step-by-Step Guide for Creating Ipe Wood Panels

A detailed step-by-step guide for creating ipe wood panels would involve several critical steps, ranging from log selection to final finishing.

- Log Selection: Choose ipe logs from sustainably managed forests, ensuring compliance with certifications like FSC.

- Milling: Use specialized machinery to precisely cut the logs into lumber, maintaining optimal grain direction and minimizing waste.

- Planning: Ensure a uniform thickness and smooth surface by using planers to remove excess wood.

- Drying: Properly dry the lumber to the appropriate moisture content to prevent warping and dimensional instability.

- Finishing: Apply protective coatings like stains, sealers, or varnishes to enhance aesthetic appeal and longevity.

- Quality Control: Implement a robust quality control system at each stage to ensure the final product meets stringent standards.

Cost and Maintenance of Ipe Wood Panels

Ipe wood panels, renowned for their exceptional durability and aesthetic appeal, often command a premium price compared to other exterior materials. Understanding the initial investment and ongoing maintenance is crucial for evaluating the long-term cost-effectiveness of these panels. This section delves into the factors influencing the cost, maintenance requirements, and overall value proposition of ipe wood.

General Cost Overview

Ipe wood, due to its strength, density, and resistance to rot and decay, typically commands a higher price point than comparable softwoods or engineered wood products. The cost is influenced by factors like the size of the panel, the quality of the wood, and the complexity of the project. Importantly, the premium paid for ipe often translates to significant long-term savings by minimizing the need for replacements and repairs. This premium pricing reflects the material’s superior performance and longevity, making it a worthwhile investment in many applications. A comparison with other materials like pressure-treated lumber or composite decking demonstrates the relative value proposition of ipe. For example, a large-scale residential deck constructed with ipe may initially cost more than a comparable deck made of composite material, but the long-term maintenance savings associated with ipe often outweigh the higher initial price.

Maintenance Requirements for Exterior Applications

Ipe’s inherent resistance to rot, decay, and insect infestation significantly reduces the need for regular maintenance, particularly in exterior applications. However, proper care and treatment are still essential to prolong the panels’ lifespan and preserve their beauty. Regular cleaning with mild soap and water, followed by rinsing, is typically sufficient to remove dirt and debris. Occasional sealing with a clear exterior wood sealant can further enhance the longevity and protect the wood’s natural oils. This helps maintain its natural color and weather resistance.

Long-Term Durability and Cost-Effectiveness

The long-term durability of ipe wood panels is a key factor in their cost-effectiveness. The high density and natural oils in ipe make it incredibly resistant to weathering, insects, and moisture. This translates into minimal maintenance and the potential for decades of use with minimal replacement or repair. For instance, a well-maintained ipe fence or deck can easily last for 30-50 years with minimal upkeep, substantially lowering the total cost of ownership over the life of the structure. This contrasts sharply with other materials, which might require significant repairs or replacement within a shorter time frame.

Factors Influencing Ipe Panel Cost

Several factors affect the price of ipe wood panels. The most significant include the species of ipe, the quality of the wood (knots, defects), the size and shape of the panels, and the location of the supplier. Variations in these factors lead to fluctuations in price, and it’s crucial to understand these influences when making purchasing decisions. Additionally, any specialized treatments or finishes applied during manufacturing will also impact the overall cost. Furthermore, sourcing from sustainable and ethical suppliers contributes to a higher price but supports responsible forest management practices.

Estimated Costs and Maintenance Schedules

| Application | Estimated Initial Cost (per sq ft) | Estimated Maintenance Schedule (per year) |

|---|---|---|

| Residential Decking | $10-$25 | Light cleaning (every 3-6 months), occasional sealant (every 2-3 years) |

| Commercial Facades | $15-$30 | Regular cleaning (every 6 months), periodic sealant application (every 5 years) |

| Exterior Fencing | $8-$18 | Regular cleaning (every 6 months), periodic pressure washing (every 2 years) |

| Outdoor Furniture | $20-$40+ | Regular cleaning (every 3-6 months), occasional oiling (every 1-2 years) |

Note: Costs are estimates and can vary based on specific project requirements, geographic location, and supplier. Maintenance schedules are guidelines and may need adjustments based on local weather conditions and specific panel treatments.

Sustainability and Ethical Sourcing of Ipe Wood

Ipe wood, renowned for its durability and aesthetic appeal, faces scrutiny regarding its environmental impact. Understanding the sustainability of its harvesting practices and responsible sourcing is crucial for its continued use in construction and design. This section explores the ethical considerations surrounding ipe wood, examining its ecological footprint and highlighting responsible sourcing initiatives.

Sustainability of Ipe Wood Harvesting Practices

Ipe wood’s durability and strength stem from its rapid growth in tropical regions. However, this rapid growth does not guarantee sustainable harvesting. Unsustainable practices can lead to deforestation and habitat loss. Responsible harvesting methods prioritize maintaining the health of the forest ecosystem. These methods typically involve selective logging, leaving mature trees to regenerate, and ensuring the survival of the species. Replanting and reforestation programs play a critical role in mitigating the impact on the surrounding environment. Strict adherence to regulations and permits, as well as community involvement, are crucial components of sustainable harvesting.

Responsible Sourcing of Ipe Wood

Responsible sourcing of ipe wood goes beyond simply adhering to regulations. It involves verifying that the wood comes from sustainably managed forests. Certification programs, like the Forest Stewardship Council (FSC) and the Programme for the Endorsement of Forest Certification (PEFC), provide a framework for responsible forestry. These programs promote sustainable forest management practices by setting standards for harvesting, replanting, and forest conservation. Companies committed to ethical sourcing will often demonstrate their adherence to these certifications on their products or websites. Thorough due diligence and transparency in the supply chain are paramount for consumers to make informed choices.

Environmental Impact of Using Ipe Wood

Using ipe wood, like any wood product, has an environmental impact. The impact depends largely on harvesting and sourcing practices. Sustainable practices minimize the negative impact. However, deforestation, habitat loss, and biodiversity decline can occur with unsustainable logging. The carbon sequestration capacity of the forest is also affected by unsustainable harvesting. The carbon stored in trees is released when the wood is harvested, contributing to greenhouse gas emissions. Choosing ipe from responsibly managed forests helps mitigate this environmental impact.

Companies Prioritizing Ethical and Sustainable Ipe Sourcing

Several companies prioritize ethical and sustainable sourcing of ipe wood. These companies demonstrate their commitment by adhering to rigorous standards and transparently communicating their sourcing practices. Examples of companies with exemplary practices are not readily available in a consolidated format. However, research and engagement with industry associations or specialized sourcing directories could reveal companies that are transparent and committed to sustainable practices. Seeking out companies that openly discuss their sustainability initiatives and certifications is crucial for consumers seeking ethical and sustainable products.

Comparison of Sustainability of Ipe Wood to Other Wood Species

| Wood Species | Sustainability Considerations | Harvesting Practices | Certification Potential |

|---|---|---|---|

| Ipe | High durability, but susceptible to unsustainable harvesting. Reliance on responsible sourcing is crucial. | Selective logging, replanting programs vital for sustainability. | FSC, PEFC certifications available for verified sustainable sources. |

| Mahogany | Known for high demand and often linked to deforestation in certain regions. | Requires rigorous assessment to ensure responsible sourcing. | Certification programs (FSC, PEFC) available for sustainably harvested mahogany. |

| Teak | High demand and its harvesting can significantly impact biodiversity. | Requires strict adherence to sustainability standards. | Certification programs (FSC, PEFC) available to verify sustainable harvesting. |

| Oak | Generally more readily available from managed forests, offering better sustainability potential. | Managed forests, often certified, offer greater sustainability. | Certifications like FSC and PEFC can be readily available. |

This table provides a comparative overview of sustainability considerations for various wood species. Each species has unique characteristics regarding its growth patterns, demand, and potential environmental impact. The information provided is not exhaustive and is meant to highlight key differences. Further research is encouraged to gain a deeper understanding of specific species.

Design Considerations for Ipe Wood Panels

Ipe wood panels, renowned for their exceptional durability and aesthetic appeal, offer a wide range of design possibilities for various projects. Understanding their unique characteristics and potential challenges is crucial for successful integration into a design scheme. Careful consideration of these factors can lead to stunning and enduring results.

The inherent beauty of ipe wood, coupled with its remarkable strength and resistance to decay, makes it a captivating material for both interior and exterior applications. Its rich, dark brown hue and distinctive grain patterns create a sophisticated and elegant presence, often enhancing the overall aesthetic of a space.

Aesthetic Qualities of Ipe Wood Panels

Ipe wood possesses a rich, dark brown tone that can range from a deep espresso to a rich chocolate hue. Its natural grain patterns are often pronounced, adding visual texture and depth to any design. The smooth, almost polished appearance of well-finished ipe wood further enhances its aesthetic appeal. This contributes to a sophisticated and luxurious feel, making it a desirable choice for projects requiring a touch of elegance.

Design Possibilities of Ipe Wood Panels

Ipe wood panels are versatile and can be incorporated into a multitude of design projects. They can serve as flooring, wall cladding, cabinetry, or even outdoor decking. The inherent durability and water resistance of ipe make it an excellent choice for outdoor applications, where it can withstand harsh weather conditions and maintain its beauty for decades. Its strength also allows for creative architectural features, such as intricate paneling and custom furniture.

Potential Challenges in Designing with Ipe Wood Panels

One potential challenge is the relatively high cost of ipe wood compared to other wood species. Furthermore, the density of ipe can make it more challenging to work with than softer woods, requiring specialized tools and techniques for cutting, shaping, and installation. Proper planning and potentially seeking expert advice are essential for overcoming these obstacles. Careful consideration of the project’s budget and the required skill level are important factors.

Comparison of Design Possibilities with Other Wood Species

Compared to other wood species, ipe stands out for its exceptional durability and weather resistance. While other woods, such as teak or mahogany, might offer similar aesthetic appeal, ipe’s longevity and resistance to rot and insect damage give it a distinct advantage in outdoor applications. The rich color and distinct grain pattern of ipe provide a unique aesthetic that is often sought after.

Examples of Interior Design Projects Featuring Ipe Wood Panels

A stunning example of an interior design project incorporating ipe wood panels is a modern kitchen featuring ipe wood cabinetry. The rich brown tones of the ipe create a warm and inviting atmosphere, while the smooth finish of the panels complements the sleek lines of the modern design. Another example might be a contemporary living room with ipe wood flooring. The warm tones and natural grain patterns of the wood add a touch of sophistication and elegance to the space, while its durability ensures longevity.

Installation and Finishing of Ipe Wood Panels

Ipe wood panels, renowned for their durability and beauty, require careful installation and finishing to maximize their lifespan and aesthetic appeal. Proper procedures ensure a seamless integration into the project, highlighting the natural elegance of the wood. A comprehensive understanding of installation methods and finishing options is crucial for achieving a professional and long-lasting result.

Proper Installation Procedures

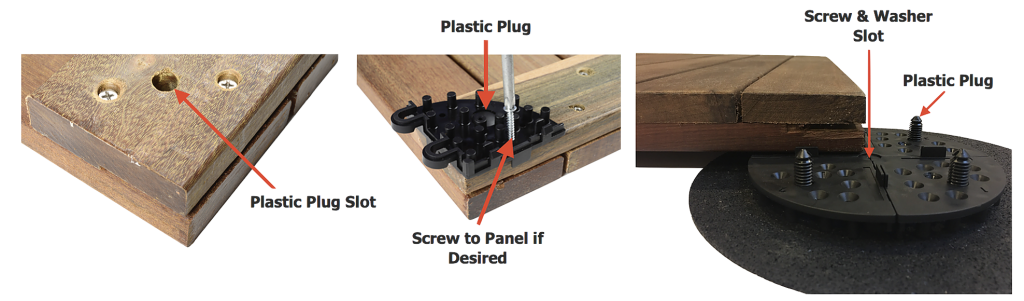

The success of an ipe wood panel installation hinges on meticulous preparation. A level and stable substrate is essential for preventing future warping or shifting. This involves careful surface preparation, ensuring the base is clean, dry, and free of debris. Prioritize using appropriate fasteners and adhesives, considering the panel’s size and weight, as well as the supporting structure. Precise measurements and careful alignment are key to a visually appealing and structurally sound installation. Adhering to manufacturer guidelines is critical for optimal results.

Finishing Options for Ipe Wood Panels

Ipe wood’s inherent beauty can be enhanced through various finishing options. Staining, for instance, can deepen the wood’s color and tone. Choosing the right stain color is crucial to complementing the surrounding environment. Sealing is equally important, acting as a protective barrier against moisture, UV rays, and potential staining or discoloration. A high-quality sealant extends the lifespan of the panels, preserving their original appearance. Applying multiple coats, following the sealant manufacturer’s instructions, is essential for optimal protection.

Comparison of Installation Methods

Several methods exist for installing ipe wood panels, each with its advantages and disadvantages. Direct-to-substrate installation, often using specialized adhesives, offers a seamless look but requires precise measurements and careful surface preparation. Alternatively, a frame-and-panel system provides more flexibility in accommodating uneven surfaces and complex designs. This method, however, might introduce visible framing elements. The chosen method should align with the specific project requirements and aesthetic goals.

Tips for Professional-Looking Installations

Achieving a professional installation of ipe wood panels requires attention to detail. Properly aligning panels is critical for a clean, seamless look. Using a spirit level to ensure flatness and minimize gaps between panels is essential for a professional finish. Employing quality tools, such as specialized panel clamps or spacers, ensures precision and avoids potential damage to the panels. Regularly checking measurements and alignment throughout the installation process is a crucial practice.

Comprehensive Guide to Preparation and Installation

A comprehensive guide to ipe wood panel installation includes the following key steps:

- Surface Preparation: Thoroughly clean and prepare the substrate to ensure a stable and level surface. Remove any loose debris, unevenness, or imperfections. Ensure the substrate is dry and free from moisture, as moisture can affect adhesion and longevity.

- Panel Measurement and Cutting: Accurately measure and cut the panels to the desired dimensions. Use precise tools and techniques to minimize errors. Employ a circular saw or a jigsaw for cutting, ensuring the edges are smooth and clean.

- Fastener Selection and Application: Choose appropriate fasteners based on the panel type and supporting structure. Apply fasteners according to manufacturer recommendations, ensuring proper spacing and penetration.

- Panel Alignment and Placement: Carefully align the panels, ensuring they are level and correctly positioned. Use shims or spacers as needed to maintain consistent spacing between panels. Double-check for straight lines and consistent gaps.

- Finishing Application: Apply a chosen finish, such as stain or sealant, following the manufacturer’s instructions. Multiple coats may be necessary for complete coverage and protection. Allow sufficient drying time between coats.

Troubleshooting and Repair of Ipe Wood Panels

Maintaining the beauty and longevity of ipe wood panels requires proactive attention to potential issues. Proper installation, regular inspection, and prompt repairs are crucial for preserving the investment and aesthetic appeal of these high-quality panels. Understanding the common problems and their solutions is essential for homeowners and contractors alike.

Potential Problems with Ipe Wood Panels

Ipe wood, renowned for its durability, can still experience issues over time. These can range from minor surface blemishes to more significant structural problems. Factors like moisture exposure, improper installation, and environmental conditions can contribute to warping, cracking, and rot. These issues, if left unaddressed, can lead to further damage and compromise the structural integrity of the panels.

Methods for Repairing and Restoring Damaged Ipe Wood Panels

Several methods exist for repairing damaged ipe wood panels, depending on the severity of the issue. For minor surface scratches or blemishes, careful sanding and refinishing can restore the original beauty. More substantial damage may necessitate specialized repairs, such as replacing affected sections or applying structural supports. A qualified professional can assess the extent of the damage and recommend the most suitable repair approach.

Common Issues Arising with Ipe Wood Panels Over Time

Common issues that may arise over time include warping, cracking, or rot, particularly in areas exposed to moisture. Expansion and contraction due to temperature fluctuations can also contribute to warping and cracking, especially in large or unsupported panels. Furthermore, improper sealing or lack of regular maintenance can lead to the development of mold or mildew, necessitating thorough cleaning and treatment.

Steps to Take When Dealing with Problems with Ipe Wood Panels

When faced with problems such as water damage, immediate action is crucial to prevent further deterioration. First, identify the source of the water damage and take steps to stop the water ingress. Next, carefully remove any affected wood and thoroughly dry the surrounding areas. If necessary, consult with a professional for a proper assessment and repair strategy. Preventing future issues involves employing proper installation techniques and providing appropriate protection from the elements.

Troubleshooting Table for Ipe Wood Panels

| Potential Problem | Description | Solutions |

|---|---|---|

| Warping | Panels bend or curve out of their original shape. | Adjusting support structures, using moisture-resistant materials, or replacing affected sections. |

| Cracking | Development of fissures or splits in the wood. | Repairing with epoxy or wood filler, reinforcing the area with structural supports, or replacing affected sections. |

| Rot | Decaying of the wood due to moisture exposure. | Removing affected wood, treating the area with fungicides, and repairing with a suitable replacement material. |

| Water Damage | Damage caused by excessive moisture. | Stopping the water ingress, removing affected wood, drying the area thoroughly, and repairing or replacing damaged sections. |

| Surface Blemishes | Scratches, dents, or other surface imperfections. | Sanding, refinishing, or using touch-up paint to restore the original finish. |

Conclusive Thoughts

Source: woodfixes.com

In conclusion, ipe wood panels offer a compelling blend of beauty, durability, and sustainability. From their impressive resistance to weathering and rot to their attractive grain patterns, ipe wood panels provide an enduring solution for a wide range of applications. By understanding their characteristics, manufacturing processes, and installation requirements, you can make informed decisions when considering these remarkable panels for your next project. The potential for aesthetic impact and long-term value is undeniable.