Ipe Wood Lumber A Comprehensive Guide

Ipe wood lumber, renowned for its exceptional durability and beauty, is a popular choice for outdoor applications. This material, sourced from specific regions, boasts a range of grades and types, each with unique properties affecting its use and value. Understanding its origins, characteristics, and processing methods is key to making informed decisions about its application and long-term maintenance.

From its initial harvesting to its final use in furniture, decking, or cladding, Ipe lumber’s journey involves several stages. This guide will delve into the various aspects of this fascinating material, from its physical and mechanical properties to its environmental impact and sustainable sourcing. We’ll also examine the market trends, cost variations, and essential maintenance practices for this robust wood.

Overview of Ipe Wood Lumber

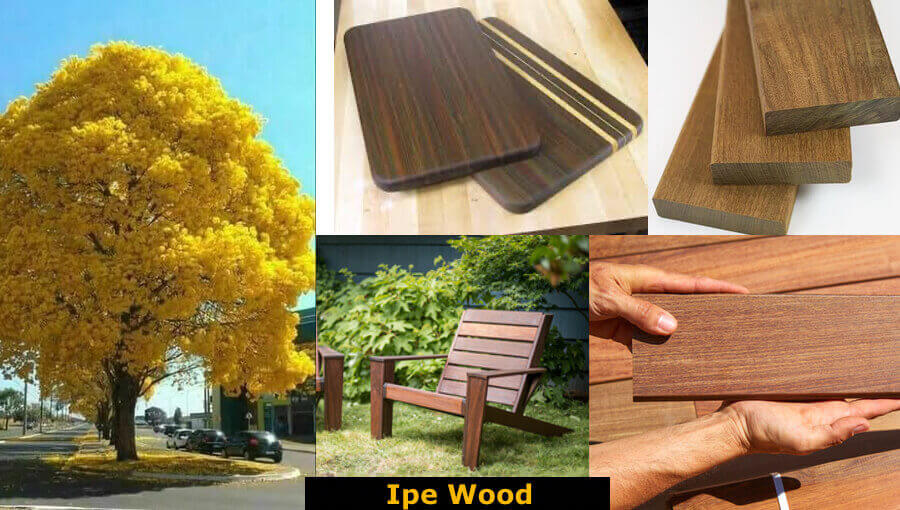

Ipe wood, renowned for its exceptional strength, durability, and aesthetic appeal, is a highly sought-after hardwood for a variety of applications. Its resistance to decay and rot, combined with its rich, dark brown color, makes it a popular choice for outdoor structures and decking. This overview delves into the key characteristics, origins, grades, and types of Ipe wood lumber.

Ipe’s inherent qualities make it a premium material. Its dense structure contributes significantly to its resilience against weather, insects, and moisture. This translates into a long lifespan for structures made with Ipe, making it a cost-effective choice in the long run, despite its higher initial price.

Key Characteristics of Ipe Wood

Ipe wood is characterized by its exceptional density, hardness, and resistance to decay and insect infestation. These properties are primarily due to its high lignin content and the presence of specific compounds that create a natural defense mechanism against biological degradation. Its rich, dark brown color and distinctive grain pattern further enhance its aesthetic appeal.

Origin and Geographical Distribution

The Ipe tree is native to the tropical rainforests of South America, primarily Brazil, Colombia, and other parts of the Amazon basin. Its geographical distribution is limited to these regions, and the specific types and variations may vary depending on the location. Sustainably sourced Ipe is crucial for maintaining the ecological balance of these forests.

Grades and Types of Ipe Wood Lumber

Ipe wood lumber is available in various grades, each reflecting its quality and suitability for specific applications. These grades are typically determined by factors such as knot size, presence of defects, and the consistency of the wood’s properties across the board.

Comparison of Ipe Wood Lumber Grades

| Grade | Density (g/cm³) | Strength (MPa) | Durability (Years) |

|---|---|---|---|

| Premium | 0.85-0.95 | 60-80 | >30 |

| Commercial | 0.75-0.85 | 50-70 | 20-30 |

| Utility | 0.65-0.75 | 40-60 | 10-20 |

This table illustrates the typical density, strength, and durability ranges for different Ipe grades. Note that these values are approximate and can vary depending on the specific tree and processing methods. Higher grades generally translate to higher performance in demanding applications.

Properties and Applications: Ipe Wood Lumber

Ipe wood, renowned for its exceptional strength and durability, stands out among other hardwoods. Its unique properties make it a highly sought-after material for demanding applications, particularly in outdoor environments. This section delves into the specifics of these properties and highlights their diverse range of applications.

Ipe wood’s remarkable resistance to rot, decay, and insect infestation stems from its dense structure and high concentration of natural oils. This inherent resilience allows it to endure harsh weather conditions and biological threats, making it a premier choice for long-lasting outdoor constructions. Its strength and stability also contribute to its widespread use in various applications.

Physical and Mechanical Properties

Ipe wood possesses a dense, hard texture, contributing to its exceptional strength and durability. Its high specific gravity means it’s significantly heavier than many other woods, resulting in excellent resistance to bending and warping. This density also contributes to its remarkable resistance to impact and abrasion. The inherent hardness of the wood, coupled with its tight grain structure, leads to minimal shrinkage and swelling, enhancing its stability in varying environmental conditions.

Exceptional Durability

Ipe wood’s exceptional durability is a direct consequence of its inherent resistance to decay and insect infestation. Its high oil content acts as a natural preservative, hindering the growth of microorganisms and pests. This natural protection makes it ideal for applications exposed to harsh weather, including direct sunlight, moisture, and extreme temperatures. This resistance to decay and insect damage translates into a significantly longer lifespan compared to other wood types, reducing the need for costly maintenance and replacements.

Applications of Ipe Wood Lumber

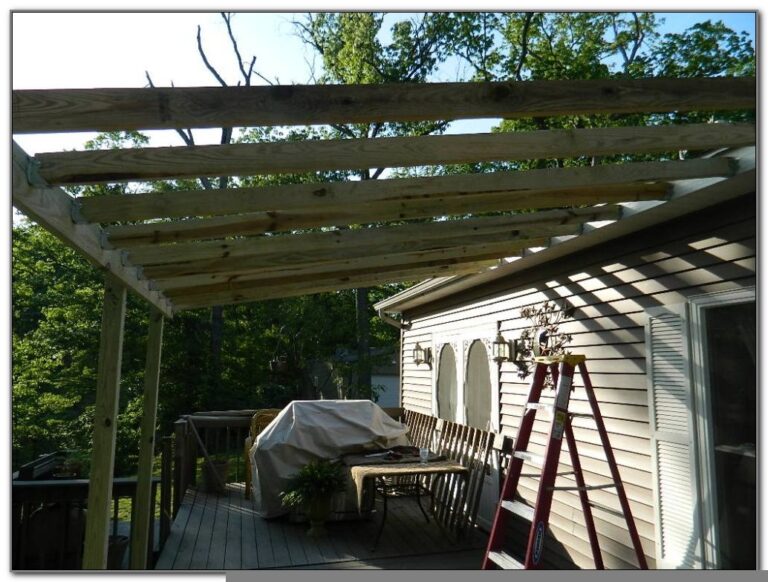

Ipe wood is a popular choice for a variety of outdoor applications due to its exceptional durability and aesthetic appeal. Its strength and resistance to the elements make it ideal for creating long-lasting and beautiful structures.

Common Applications and Advantages

| Application | Advantages | Images (description) |

|---|---|---|

| Outdoor Furniture | Exceptional durability, weather resistance, and attractive appearance. It can withstand harsh weather conditions, ensuring furniture longevity. | Imagine meticulously crafted patio furniture, with a rich brown hue, standing tall against a backdrop of vibrant foliage. The wood’s smooth texture is apparent, showcasing the natural beauty and strength of the material. |

| Decking | Superior resistance to moisture, rot, and insect damage. This translates to a long-lasting and low-maintenance decking surface, ideal for patios, balconies, and other outdoor areas. | Visualize a sturdy, evenly spaced deck built from Ipe planks. The planks are a deep brown color, displaying the natural beauty of the wood. The deck is situated in a lush garden setting, with greenery and trees as a backdrop. |

| Cladding | Exceptional resistance to weather damage and pest infestation. Its aesthetic appeal enhances the architectural beauty of structures while providing long-term protection. | Picture a building facade, meticulously crafted from large, vertically oriented Ipe planks. The planks are a dark brown color, and their smooth, even texture creates a visually appealing contrast with the surrounding environment. The building looks well-maintained and sturdy. |

| Exterior Siding | Exceptional durability, weather resistance, and longevity. The material’s natural beauty complements various architectural styles, adding a touch of sophistication to the structure. | Envision a house with a siding made from Ipe wood planks. The siding is a rich, dark brown color, and the wood’s natural grain is visible. The house looks well-maintained, and the siding complements the overall architectural style. |

Manufacturing and Processing

Source: caribteak.com

Ipe wood, renowned for its durability and aesthetic appeal, undergoes a meticulous manufacturing process to achieve its final form. This process, from the initial felling to the finished lumber, involves several crucial steps that significantly impact the wood’s quality and longevity. Understanding these steps provides insight into the careful consideration and meticulousness involved in producing high-quality Ipe lumber products.

The process of transforming Ipe logs into usable lumber involves a series of steps, starting with responsible harvesting and continuing through various processing stages. Careful attention to each step is essential to ensure the quality and sustainability of the final product.

Harvesting and Felling

The initial stage of Ipe lumber production involves responsible harvesting practices. Selective logging, focusing on mature trees and minimizing damage to surrounding vegetation, is crucial. Proper felling techniques prevent damage to the remaining forest ecosystem and ensure that the harvested wood is sound and suitable for processing. Specialized equipment and trained personnel are often used to minimize environmental impact and maximize the yield of high-quality lumber.

Processing and Shaping

After felling, the Ipe logs are transported to processing facilities. Here, the logs are meticulously debarked and then sawn into lumber of desired dimensions. Advanced machinery and precise cutting techniques ensure minimal waste and consistent lumber dimensions. Quality control measures are integrated throughout the process to guarantee the standards and specifications required by the market.

Drying and Treatment, Ipe wood lumber

The drying process is critical to the longevity and stability of Ipe lumber. Kiln drying is a common method used to control the moisture content of the lumber, preventing warping, cracking, and decay. Different drying methods and techniques are employed to maintain the wood’s natural properties and durability. The specific methods employed depend on factors like the size of the lumber and the intended application.

Methods of Drying

- Kiln drying: This method uses controlled environments and temperatures to remove moisture from the lumber. This process is generally faster and more efficient than air drying, while ensuring consistent moisture levels.

- Air drying: A more traditional method that involves exposing the lumber to open air and sunlight to slowly reduce moisture content. While slower, it is often more cost-effective.

Methods of Treatment

- Preservative treatments: Chemical treatments can be applied to enhance the resistance of Ipe to decay and insect damage. These treatments significantly increase the longevity of the wood, especially in high-humidity environments or areas with known pest infestations.

Environmental Impact Considerations

The production of Ipe lumber, like any forestry operation, has environmental implications. Sustainable harvesting practices, including selective logging and reforestation efforts, are essential to minimize the impact on the surrounding ecosystem. The use of sustainable harvesting practices ensures the long-term health of the forests and the availability of Ipe lumber for future generations. Careful consideration of transportation methods and waste management practices is also crucial in mitigating environmental concerns.

Manufacturing Flowchart

| Step | Description |

|---|---|

| 1 | Harvesting: Selective logging of mature Ipe trees. |

| 2 | Transporting: Transporting the harvested logs to the processing facility. |

| 3 | Debarking: Removing the bark from the logs. |

| 4 | Sawing: Cutting the logs into lumber of desired dimensions. |

| 5 | Drying: Kiln drying or air drying to reduce moisture content. |

| 6 | Treatment (Optional): Applying preservatives for enhanced durability. |

| 7 | Quality Control: Inspection and grading of the lumber. |

| 8 | Packaging: Packaged the finished lumber for shipment. |

Market Trends and Economics

Ipe wood lumber, prized for its durability and aesthetic appeal, faces dynamic market forces. Understanding these trends is crucial for informed investment and strategic planning within the industry. Current market conditions, influenced by global demand and supply fluctuations, directly impact pricing and availability.

The Ipe wood market is characterized by a complex interplay of factors, from sustainable harvesting practices to international trade regulations. These elements, alongside economic shifts and consumer preferences, contribute to the overall market dynamics.

Current Market Trends

The current market trend for Ipe wood lumber reveals a sustained demand, fueled by its exceptional performance in exterior applications. Demand for Ipe wood has been consistently high in the construction and decking sectors, particularly in regions with high humidity and exposure to harsh weather conditions. However, supply chain challenges and environmental concerns related to sustainable harvesting continue to impact the availability and price of Ipe.

Supply and Demand Dynamics

Supply of Ipe wood is often constrained by the need for responsible harvesting and reforestation efforts. The natural growth rate of Ipe trees is relatively slow, making replenishment a considerable factor. This slower growth rate, coupled with increasing demand, results in a relatively tight supply in the market. These factors often lead to price fluctuations, influenced by both natural and man-made events.

Factors Influencing Price Fluctuations

Several factors contribute to the price volatility of Ipe lumber. These include fluctuations in the cost of transportation, labor, and raw materials, as well as changes in global economic conditions. Furthermore, government regulations, especially those related to sustainable forestry practices and import/export tariffs, significantly impact the price of Ipe lumber. The interplay of these factors is constantly reshaping the Ipe market, making it important to track and understand the nuances of the market.

Global Trade of Ipe Wood Lumber

The global trade of Ipe wood lumber is a complex network of suppliers, importers, and exporters. The major exporting regions are typically those with significant Ipe forests, while import demand is concentrated in regions with a high demand for high-quality exterior lumber. International trade regulations and import/export tariffs, as well as sustainability certifications, play a crucial role in shaping the movement of Ipe lumber across borders. Transparency in the supply chain is increasingly important, especially for buyers concerned about ethical and sustainable sourcing.

Cost Variations by Grade and Quantity

The cost of Ipe lumber varies significantly based on grade and quantity. Higher grades, exhibiting superior quality and fewer defects, command higher prices. Similarly, larger quantities often come with discounts, reflecting economies of scale.

| Grade | Quantity (cubic meters) | Price (USD/m³) |

|---|---|---|

| Premium | 10 | $15,000 |

| Premium | 100 | $12,000 |

| Premium | 1000 | $10,000 |

| Standard | 10 | $10,000 |

| Standard | 100 | $8,000 |

| Standard | 1000 | $6,000 |

Note: The table above provides illustrative examples of cost variations. Actual prices will fluctuate based on the specific market conditions, including the grade, quantity, and source of the Ipe lumber.

Sustainability and Ethical Sourcing

Source: woodworkmag.com

Ipe wood, prized for its durability and beauty, faces increasing scrutiny regarding its sustainable sourcing. The rapid growth of demand for this hardwood necessitates careful consideration of the environmental impact of its harvesting and trade. This section explores the sustainability concerns, responsible forestry practices, and certification programs vital for ensuring the long-term availability and ethical use of Ipe.

Responsible forestry practices and sustainable harvesting are paramount for the long-term viability of Ipe wood production. Deforestation and unsustainable logging can lead to habitat loss, soil erosion, and biodiversity decline. Sustainable practices aim to minimize these negative impacts by balancing resource extraction with the preservation of forest ecosystems.

Sustainability Concerns

Ipe forests, often located in tropical regions, are vulnerable to deforestation due to unsustainable logging practices. Illegal logging, lacking proper permits and oversight, often results in significant environmental damage. The high demand for Ipe lumber has, in some cases, driven unsustainable harvesting practices, threatening the long-term health of the forests and the availability of this valuable timber.

Responsible Forestry Practices

Sustainable forestry practices are crucial for the preservation of Ipe forests. These practices encompass a range of measures designed to balance resource extraction with the conservation of biodiversity and ecosystem health. Reforestation efforts, along with the careful selection and management of harvesting areas, play a vital role in ensuring the continued availability of Ipe. Monitoring and auditing harvesting operations by independent organizations help guarantee adherence to sustainable practices.

Sustainable Harvesting

Sustainable harvesting strategies emphasize selective logging, minimizing the impact on the forest ecosystem. Selective cutting leaves behind mature trees to regenerate the forest naturally, maintaining the health of the ecosystem and supporting biodiversity. Furthermore, controlled logging areas are carefully chosen to minimize the disruption to the surrounding environment. Replanting or reforestation efforts often accompany sustainable harvesting to compensate for extracted timber and support forest regeneration.

Certification Programs

Certification programs provide a framework for ensuring the responsible sourcing and use of Ipe wood. These programs verify that the timber meets specific sustainability standards, offering consumers assurance that the wood they purchase comes from well-managed forests. The credibility and acceptance of a certification program influence the market value and consumer preference for the product.

| Certification Program | Criteria | Verification Process |

|---|---|---|

| Forest Stewardship Council (FSC) | Focuses on environmental protection, social equity, and economic viability. Includes criteria related to biodiversity conservation, community engagement, and responsible labor practices. | Third-party audits assess compliance with FSC standards. Regular monitoring and verification ensure ongoing adherence. |

| Programme for the Endorsement of Forest Certification Schemes (PEFC) | Promotes sustainable forest management through a range of criteria, including biodiversity protection, forest health, and social considerations. | Independent certification bodies verify compliance with PEFC standards. Chain-of-custody certification ensures that the product is traced from forest to consumer. |

| PEFC/COC (Chain of Custody) | Focuses on the responsible handling and processing of timber from the forest to the final product. | Evaluates and certifies the entire supply chain, ensuring that the wood used in the final product adheres to the standards set by the PEFC certification scheme. |

Maintenance and Care

Source: ipedeckinghq.org

Ipe wood, renowned for its durability, requires minimal maintenance compared to other hardwoods. However, proper care prolongs its lifespan and enhances its aesthetic appeal, preserving its rich beauty and robust performance. Regular cleaning and occasional treatments are key to maintaining the integrity and longevity of Ipe.

Maintaining the beauty and resilience of Ipe involves understanding its inherent properties and implementing appropriate care strategies. This includes recognizing the types of treatments that best complement its natural resistance to decay and weathering.

Proper Cleaning Methods

Regular cleaning is essential to prevent the accumulation of dirt, grime, and mildew, which can compromise the wood’s appearance and potentially lead to degradation. Using mild soap and water is usually sufficient. Avoid harsh chemicals or abrasive cleaners, which can damage the wood’s surface.

Suitable Treatments and Finishes

Ipe’s natural oils provide inherent protection against the elements. However, a protective sealant or finish can further enhance its durability and appearance, especially in high-moisture or harsh-weather conditions. Staining or sealing treatments, if applied, should be compatible with the intended application and environment.

- Oil-based finishes offer excellent protection against moisture and UV exposure, preserving the natural beauty of the wood. They can be applied regularly to maintain the wood’s sheen and repel moisture.

- Water-based finishes are also effective in protecting Ipe from the elements and enhancing its aesthetic appeal. These finishes offer an environmentally friendly alternative while still providing a robust barrier.

- A clear sealant can enhance the wood’s natural color and protect it from damage. Regular application helps maintain the Ipe’s pristine look.

Longevity with Proper Maintenance

Proper maintenance significantly impacts the longevity of Ipe. With regular cleaning and appropriate treatments, Ipe can last for decades, offering a long-term investment in outdoor structures. The lifespan of Ipe decking, for instance, can easily surpass 25 years in moderate climates, showcasing the durability of the wood. In harsh climates, where exposure to extreme weather is frequent, periodic maintenance is crucial.

Step-by-Step Guide to Maintaining Ipe Decking

This guide articulates the steps for maintaining Ipe decking to ensure its longevity and aesthetic appeal.

- Inspection: Regularly inspect the decking for any signs of damage, such as splintering, cracking, or significant discoloration. Address any issues promptly.

- Cleaning: Use a soft-bristled brush or a pressure washer (with a low-pressure setting) to remove dirt, debris, and mildew from the decking. A mild soap solution is recommended. Avoid using abrasive cleaners.

- Drying: Allow the decking to dry thoroughly after cleaning. Water remaining on the surface can promote mildew growth.

- Treatment (Optional): If needed, apply a suitable sealant or finish to protect the decking from the elements. Follow the manufacturer’s instructions for application and drying time.

- Repair (if needed): Address any minor damage, such as small cracks or splinters, immediately using appropriate wood filler or repair techniques.

Last Recap

In conclusion, Ipe wood lumber presents a compelling option for outdoor projects due to its inherent durability and aesthetic appeal. Its properties, coupled with appropriate processing and maintenance, ensure its longevity and suitability for various applications. However, responsible sourcing and mindful use are crucial to maintain the long-term viability of this valuable resource. By understanding the factors influencing its supply, cost, and environmental impact, we can make informed choices about incorporating Ipe wood into our projects.