Restoring IPE Deck A Comprehensive Guide

Restoring IPE deck provides a detailed guide for revitalizing your weathered wooden deck. This comprehensive overview will walk you through every step, from initial assessment to long-term maintenance. Expect to learn about different damage types, various restoration methods, essential materials, and troubleshooting for common problems.

The initial assessment is crucial. Understanding the extent and type of damage—whether it’s rot, mold, splintering, or insect infestation—is the first step. The condition of the substructure (joists, beams, posts) must also be considered. This thorough inspection will inform the most appropriate restoration method. Different IPE wood types may require unique approaches, so understanding these variations is key to a successful restoration.

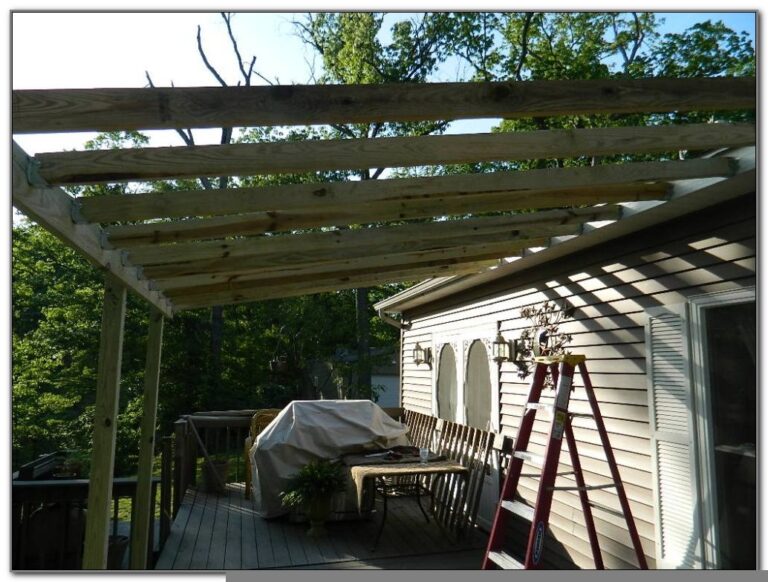

Initial Assessment

Source: calpreserving.com

A thorough assessment of the IPE deck is crucial before any restoration work begins. This initial evaluation will identify the extent of damage, pinpoint areas needing specific attention, and determine the appropriate restoration approach. Understanding the type of IPE wood used is also vital, as different species and processing methods affect the restoration process. Careful consideration of the substructure’s condition is equally important, as compromised support can compromise the entire restoration effort.

The assessment process will involve a comprehensive inspection of the deck’s surface, its substructure, and the surrounding environment. This detailed examination is paramount to crafting an effective and sustainable restoration strategy. A precise understanding of the damage’s origin and severity will ensure the restoration is both efficient and durable.

Damage Assessment

The IPE deck’s condition reveals a significant level of deterioration. Several types of damage are present, including rot in the support beams and posts, mold growth in sheltered areas, and noticeable splintering in high-traffic zones. Insect infestation is evident in some areas, particularly near the perimeter of the deck, where wood-boring beetles have left their mark. The extent of damage varies, with approximately 25% of the deck exhibiting significant rot and 15% showing signs of mold. Splintering is concentrated primarily along the edges and corners of the deck boards.

Extent of Damage

The damage to the deck is concentrated in several key areas. The southern portion of the deck shows substantial rot in the supporting joists, while the western section exhibits more extensive mold growth. The central area shows signs of splintering, primarily along the edge boards and where the joists meet the deck boards. The severity of insect infestation varies, with some areas displaying extensive damage and others showing only minor traces.

IPE Wood Types and Characteristics

Different types of IPE wood possess varying characteristics that influence the restoration process. Brazilian IPE, for example, is known for its durability and resistance to decay. However, even this high-quality wood can succumb to rot and decay if exposed to prolonged moisture or improper maintenance. Understanding the specific type of IPE used is crucial to selecting the appropriate restoration techniques and materials.

Substructure Condition

The condition of the substructure, including the joists, beams, and posts, plays a critical role in the overall success of the restoration project. A thorough inspection of the substructure is necessary to identify any structural weaknesses or deterioration. Signs of rot or insect damage in the substructure require immediate attention, as compromised support can lead to deck instability and failure. Careful examination of the substructure is crucial to determining the need for repairs or replacement.

Importance of Thorough Inspection and Restoring ipe deck

A thorough inspection before starting any restoration work is essential. Without a complete understanding of the damage’s extent and origin, any restoration work undertaken could prove ineffective or even exacerbate the problem. A proper inspection helps to avoid costly mistakes and ensure a durable and long-lasting restoration. For instance, ignoring signs of hidden rot can lead to the need for a complete replacement of the deck, significantly increasing the overall cost.

Restoration Methods

Restoring an IPE deck involves carefully selecting the appropriate methods to address damage while preserving the wood’s integrity and aesthetic appeal. Proper preparation and execution are key to achieving a long-lasting, beautiful result. Understanding the strengths and weaknesses of each method is crucial for making informed decisions.

Comparison of Restoration Methods

Various techniques can be employed to restore an IPE deck, each with its own set of advantages and disadvantages. Factors like the extent of damage, budget, and desired outcome should be considered when choosing a restoration method.

| Restoration Method | Pros | Cons | Suitable Damage Level |

|---|---|---|---|

| Sanding | Removes surface imperfections, reveals natural wood beauty, prepares for staining/sealing, and restores a smooth surface. | Time-consuming, can remove substantial wood if not careful, may require multiple applications, potential for damage to the wood if not properly executed. | Moderate to severe damage; surface scratches, minor rot, uneven discoloration. |

| Pressure Washing | Effective for removing loose dirt, debris, and mold; relatively quick; low cost compared to other methods. | Can damage the wood if pressure is too high, may not remove deeply embedded stains or mold; can potentially cause water damage or unevenness. | Light to moderate soiling; loose dirt, superficial mildew, and algae. |

| Staining | Enhances the wood’s natural color, protects the wood from UV rays, and provides a rich, aesthetically pleasing finish. | Can change the appearance of the wood if not matched correctly; requires proper preparation to adhere correctly, and can be time-consuming if multiple coats are required. | Minor damage: surface discoloration, scratches, fading. |

| Sealing | Protects the wood from moisture, UV rays, and environmental factors, prolongs the deck’s lifespan, and enhances the finish. | Can trap moisture if not properly applied; requires regular maintenance to maintain effectiveness; may require multiple coats for full protection. | All damage levels; provides long-term protection. |

Sanding Technique

Sanding is a crucial step for restoring IPE decks, especially when addressing significant damage. Proper technique prevents further damage to the wood and ensures a smooth, even surface for subsequent treatments.

Sanding IPE requires specific tools and techniques. Start by using a coarser grit sandpaper (e.g., 80-100 grit) to remove any significant imperfections or coatings. Gradually increase the grit to finer grades (e.g., 120-180 grit) to achieve a smoother finish.

Use a random orbital sander for large areas for efficiency and to avoid uneven sanding. For smaller areas, use a hand-held sanding block or sandpaper with a sanding pad. Always work with the grain of the wood. Keep the sander moving to avoid burning the wood. Clean up dust and debris regularly. Use a vacuum or tack cloth to prevent wood dust from settling on other areas of the deck or spreading into the home. Be mindful of any splinters or deep scratches that might require repair. If necessary, use wood filler to address these imperfections.

Materials and Tools

Restoring an IPE deck effectively requires careful consideration of the materials and tools used. Proper selection ensures a durable and aesthetically pleasing outcome. Choosing high-quality components is crucial for long-term performance and minimizing future repairs. This section details the necessary materials, tools, and safety precautions to undertake this project successfully.

The restoration process involves multiple steps, each requiring specific tools. Carefully selecting the appropriate materials and tools is paramount for a successful restoration. This ensures a lasting and visually appealing result, preventing future complications.

Essential Materials

Choosing the right materials for an IPE deck restoration is vital for achieving a lasting and visually appealing result. A comprehensive list includes the necessary components for repairs and maintenance.

- Wood: For repairs or replacement, select IPE lumber that matches the existing deck’s grade and species. Using the same type of wood ensures a seamless aesthetic integration.

- Stains and Sealers: High-quality stains and sealers are essential for protecting the deck from the elements. Select a stain that complements the existing deck’s color and provides long-term protection against UV rays, moisture, and mildew.

- Fasteners: Use stainless steel screws and nails for maximum durability and corrosion resistance. This is particularly important in outdoor environments to prevent rust and maintain the deck’s integrity.

- Cleaning Solutions: A suitable deck cleaner and degreaser are necessary to remove dirt, mildew, and previous treatments before staining or sealing.

Necessary Tools

The correct tools are vital for efficient and safe restoration. Having the right tools for each task will speed up the process and ensure a professional finish.

- Measuring Tools: A tape measure, level, and square are essential for accurate measurements and alignment.

- Cleaning Tools: Pressure washer, scrub brushes, and cleaning solutions for removing dirt, grime, and old sealants.

- Cutting Tools: Hand saw, circular saw, or reciprocating saw for cutting wood, depending on the repair needs. A utility knife is beneficial for smaller cuts and detail work.

- Fastening Tools: Drill, screwdriver, and impact driver are required for securing fasteners. A screwdriver set for various screw types is beneficial for efficiency.

- Sanding Tools: Sandpaper, orbital sander, and/or belt sander for smoothing surfaces and preparing for staining.

- Application Tools: Paintbrushes, rollers, and sprayers are necessary for applying stains and sealers evenly and efficiently.

Safety Equipment

Safety precautions are paramount during any deck restoration project. Protective gear prevents accidents and ensures a safe working environment.

- Eye Protection: Safety glasses or goggles to protect the eyes from debris or chemicals.

- Hearing Protection: Earmuffs or earplugs to protect hearing from power tools and machinery.

- Hand Protection: Work gloves to protect hands from cuts, abrasions, and chemicals.

- Foot Protection: Work boots or safety shoes to protect feet from sharp objects and potential slips or falls.

- Appropriate Clothing: Durable clothing to protect against dust, debris, and potential exposure to chemicals.

Importance of High-Quality Materials and Tools

High-quality materials and tools are crucial for a successful and lasting restoration. Using sub-standard components can lead to premature failure, costly repairs, and aesthetic issues. Investing in quality tools and materials minimizes the risk of problems down the line.

Supply Checklist

This checklist ensures that all necessary materials and tools are gathered before beginning the restoration project. Thorough preparation saves time and prevents delays.

| Category | Items |

|---|---|

| Wood | IPE lumber, replacement boards, screws |

| Staining/Sealing | Stains, sealers, brushes, rollers, sprayers |

| Fasteners | Stainless steel screws, nails, anchors |

| Cleaning | Pressure washer, cleaning solutions, brushes |

| Cutting | Saws, utility knife |

| Sanding | Sandpaper, sander |

| Fastening | Drills, screwdrivers, impact driver |

| Safety | Goggles, gloves, boots, and earplugs |

Step-by-Step Procedures

Restoring an IPE deck involves a methodical approach, ensuring the longevity and aesthetic appeal of the wood. This detailed guide articulates the crucial steps, from initial inspection to final sealing, emphasizing safety precautions and potential issues to mitigate risk and maximize results.

This comprehensive guide provides a structured approach to restoring your IPE deck, from the initial assessment to the final sealing process. Each step is critical, and understanding the sequence and potential challenges will help ensure a successful restoration project.

Initial Inspection and Preparation

Thorough inspection of the entire deck is essential to determine the extent of damage and necessary repairs. This involves visually assessing the wood for rot, splintering, or loose boards. Inspecting the substructure for deterioration or water damage is also critical. Documenting any observed issues is crucial for planning the restoration strategy. A visual inspection may reveal loose nails or screws, which can be a source of concern if not addressed.

Cleaning and Pressure Washing

Thoroughly clean the deck using a stiff-bristled brush and a garden hose to remove loose debris, dirt, and algae. A pressure washer is highly effective for removing stubborn stains and grime. A higher pressure setting is usually recommended, but always prioritize safety by ensuring the nozzle is kept at a safe distance. Be mindful of the pressure washer’s potential to damage the wood if the pressure is too high or the nozzle is too close. Using a cleaning solution can aid in removing any remaining dirt or stains. Be sure to follow the manufacturer’s instructions for the cleaning solution.

Repairing Damaged Boards and Substructure

This stage focuses on addressing any damage found during the inspection. Repairing or replacing damaged boards requires precision and attention to detail. Damaged boards should be removed, and the substructure should be inspected for any rot or water damage. Replacement boards should be properly fitted and secured. If significant substructure damage is found, consulting a professional may be necessary to prevent future issues. The use of appropriate fasteners, such as screws or nails, is crucial to ensure long-term stability.

Sanding and Refinishing

Thoroughly sanding the deck is essential for creating a smooth surface for the finish. Start with a coarser grit sandpaper to remove any remaining debris or old finish. Gradually progress to finer grits for a smoother surface. Use a sanding pad for larger areas. Consider the use of a sanding machine for efficiency and safety, particularly for extensive areas. After sanding, clean the deck thoroughly to remove sanding dust. Choose a suitable deck stain or sealant, ensuring it’s compatible with IPE. Apply the chosen finish evenly and allow it to dry completely.

Sealing and Final Inspection

The final step involves applying a protective sealant to the deck. A sealant will protect the wood from the elements and enhance its longevity. Use a sealant specifically designed for exterior use. Apply the sealant in thin, even coats, ensuring it penetrates the wood. Allow ample time for drying and curing. After the sealant has fully cured, inspect the deck for any imperfections. Make any necessary touch-ups to ensure a flawless finish. This step should be performed in dry conditions to prevent the sealant from drying too quickly or unevenly.

Maintenance and Long-Term Care

Source: teakmaster.com

Maintaining an IPE deck after restoration is crucial for preserving its beauty and longevity. Proper cleaning, sealing, and preventative measures are essential to protect the wood from weathering and damage. This section details strategies for maintaining your IPE deck, encompassing various maintenance schedules and the impact of environmental factors.

The key to a long-lasting IPE deck lies in consistent upkeep. By following a proactive maintenance plan, you can minimize the risk of costly repairs and ensure your investment retains its value and aesthetic appeal for years to come.

Cleaning Procedures

Regular cleaning is vital to remove dirt, debris, and mildew that can accumulate on the deck. Effective cleaning prevents these elements from damaging the wood’s surface and compromising its structural integrity. A pressure washer is often effective for removing stubborn dirt and grime. However, use caution to avoid damaging the wood’s surface, especially if the deck has recently been restored. A soft-bristled brush or sponge with mild detergent and water can also be used for more delicate cleaning.

Sealing Strategies

Applying a quality sealant is essential to protect the restored IPE from moisture damage and the elements. Sealants help maintain the wood’s natural beauty, enhance its durability, and prevent the development of mold or mildew. Re-sealing the deck annually, or more frequently depending on the level of use and environmental conditions, is recommended to maintain its water-resistance and aesthetic appeal. Select a sealant formulated for outdoor use, specifically designed for IPE wood, to ensure optimal protection.

Frequency of Maintenance

The frequency of maintenance will vary based on the level of use and environmental factors. A higher level of use, such as a deck frequently used for entertaining or recreational activities, will require more frequent cleaning and sealing. Conversely, a deck used less frequently will require less frequent maintenance.

Maintenance Schedules

| Level of Use | Cleaning Frequency | Sealing Frequency |

|---|---|---|

| Low (occasional use) | Every 2-3 months | Annually |

| Moderate (weekly use) | Every 1-2 months | Every 6-12 months |

| High (daily use) | Monthly | Annually or bi-annually |

Environmental Factors

Environmental conditions significantly influence the longevity of a restored IPE deck. Exposure to excessive moisture, intense sunlight, and extreme temperatures can accelerate deterioration. Regular monitoring and adjustment of maintenance schedules in response to these factors are crucial. For example, a deck located in a humid climate may require more frequent sealing than one in a dry climate.

Common Problems and Solutions

Various issues can arise, such as:

- Mold and Mildew: Promptly address mold or mildew growth with a suitable cleaning solution. Preventative measures like proper sealing and regular cleaning can minimize their occurrence.

- Wood Rot: Regular inspections and prompt treatment of any signs of rot are critical. Early detection and appropriate repairs are key to preventing further damage.

- Cupping and Warping: Consistent moisture levels and appropriate sealing can minimize these issues. If severe, professional assessment and repair might be necessary.

Proper maintenance and consistent vigilance will ensure that the restored IPE deck continues to enhance your property’s aesthetic appeal and durability for many years.

Troubleshooting: Restoring Ipe Deck

Source: plasticinehouse.com

Restoring an IPE deck can be a rewarding experience, but unforeseen issues can arise. Understanding potential problems and their solutions is crucial for a successful restoration project. Anticipating these challenges allows for proactive measures, minimizing costly rework and ensuring a durable, long-lasting result.

Careful observation and meticulous documentation during the initial assessment are vital. Early detection of issues often leads to simpler and more affordable solutions. This proactive approach minimizes the risk of more extensive and expensive repairs.

Common Restoration Issues

Thorough inspection of the deck is paramount to identify potential issues. Problems can range from minor surface blemishes to significant structural damage. Recognizing these problems early in the restoration process is key to preventing larger problems. Early intervention often translates to more economical and efficient repairs.

Warping

Warping in IPE decking is often caused by moisture fluctuations or uneven drying. Exposure to prolonged periods of high humidity can cause expansion, while prolonged drought can lead to shrinkage. This leads to uneven surfaces, making the deck susceptible to further damage or creating tripping hazards. Addressing the moisture issue is crucial to prevent further warping.

Staining

Staining can be caused by a variety of factors, including exposure to harsh weather conditions, improper cleaning methods, or lingering residues from previous treatments. Improper cleaning agents or inadequate rinsing can leave behind residues, while prolonged exposure to sunlight can lead to fading or discoloration. Identifying the source of the stain is critical for effective removal.

Structural Damage

Structural damage in IPE decks is often linked to significant environmental exposure, such as severe weather events (high winds, heavy rain, or hail) or improper installation. Signs include cracking, splitting, or loose boards. Professional evaluation is often necessary to assess the extent of the damage and determine the best course of action. Prompt action is necessary to prevent further damage and ensure the safety of the deck.

Table of Common Problems and Solutions

| Problem | Possible Cause | Solution |

|---|---|---|

| Warping | Moisture fluctuations, uneven drying, improper installation | Assess moisture content; use moisture meters to determine the level of moisture in the wood; consider professional consultation to assess structural integrity if warping is extensive; consider a treatment to stabilize the moisture content of the wood. |

| Staining | Harsh weather, improper cleaning, lingering residues | Identify the source of the stain; use appropriate cleaning agents; consider professional cleaning services for stubborn stains; consult with experts to determine the best treatment based on the stain type. |

| Structural Damage | Severe weather, improper installation, insufficient support | Assess the extent of the damage with a professional; replace damaged boards or support structures; implement reinforcement measures; consider professional structural engineering if damage is significant. |

Concluding Remarks

In conclusion, restoring an IPE deck is a multi-faceted process that requires careful planning and execution. By following this guide, you’ll be equipped to tackle any damage, select the right restoration methods, and maintain your deck for years to come. Remember that preventative measures are essential, and understanding potential issues and their solutions is key to a successful outcome. From the initial inspection to the final sealing, this guide ensures a smooth and satisfying restoration process.