ISPM 15 Lumber Global Trade Requirements

ISPM 15 lumber sets the international standard for exporting wood products, ensuring they meet global pest-risk management protocols. This comprehensive guide delves into the intricacies of compliance, from defining the standard itself to its impact on international trade. Understanding the regulations is crucial for manufacturers and exporters alike to successfully navigate the global market.

The document covers everything from defining ISPM 15 and its historical context to the specific requirements for different types of lumber. It also explores the documentation needed for certification, the logistical challenges and opportunities, and the enforcement mechanisms in place. Finally, practical examples and detailed procedures are provided to facilitate successful compliance.

Defining ISPM 15 Lumber

ISPM 15 is a crucial international standard that addresses the prevention of the spread of wood pests through the movement of regulated commodities, including lumber. It’s a vital tool for ensuring the safety and health of forests worldwide. Understanding its definition, purpose, and implications is essential for anyone involved in the global lumber trade.

The standard’s primary objective is to minimize the risk of introducing invasive pests into new environments through the international movement of lumber. It provides a framework for countries to establish consistent procedures and requirements for the treatment and certification of lumber products destined for export or import. This ultimately safeguards ecosystems from devastating pest infestations.

ISPM 15 Definition

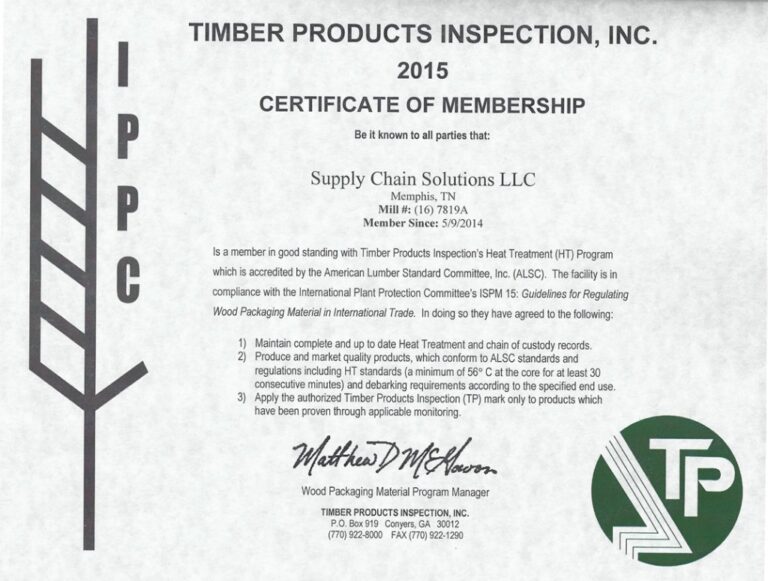

ISPM 15, or the International Standard for Phytosanitary Measures 15, is a globally recognized standard developed by the International Plant Protection Convention (IPPC). It specifies the requirements for the treatment and/or certification of regulated commodities, such as lumber, to prevent the introduction and spread of wood-boring insects and other pests. This preventative approach safeguards forests and agricultural lands.

Purpose and Objectives of ISPM 15 Regarding Lumber

The core purpose of ISPM 15 for lumber is to protect countries from the introduction of wood-boring insects and other pests that could severely damage native forests and agricultural lands. It mandates that lumber products exported or imported must meet specific phytosanitary requirements, either through treatment or certification. The objectives include preventing the spread of these pests, maintaining the health of forests, and reducing economic losses due to pest infestations.

Historical Context and Evolution of ISPM 15

ISPM 15 evolved from the need for a standardized approach to regulating the movement of wood products across international borders. The increasing globalization of trade highlighted the critical role of preventative measures in safeguarding global forests. Early iterations of the standard focused on establishing baseline requirements for treatment and certification. Over time, the standard has been refined and updated to reflect evolving pest risks and best practices. The constant refinement reflects the dynamic nature of the global landscape of pests.

Key Differences Between ISPM 15 and Other Relevant International Standards

ISPM 15 is distinct from other international standards, such as those focused on timber grading or quality control. While those standards address aspects of lumber production and handling, ISPM 15 focuses exclusively on phytosanitary requirements. It emphasizes the prevention of pest introduction, a distinct focus compared to standards that prioritize physical attributes or market demands. ISPM 15 distinguishes itself through its explicit emphasis on plant health.

Main Actors Involved in the Implementation and Enforcement of ISPM 15

The implementation and enforcement of ISPM 15 involve multiple actors at national and international levels. National plant protection organizations (PPPOs) play a critical role in implementing the standard within their respective countries. These organizations are responsible for inspecting lumber products, verifying treatments, and issuing certificates. International organizations like the IPPC provide guidance and coordination among countries to ensure consistent application. Furthermore, exporters and importers of lumber are accountable for adhering to the requirements of Artikeld in ISPM 15.

Requirements for ISPM 15 Lumber

ISPM 15, the International Standard for Phytosanitary Measures, mandates specific treatments and procedures for lumber to prevent the spread of wood-borne pests during international trade. Adherence to these requirements is crucial for safeguarding global forests and agricultural ecosystems. Failure to comply can result in significant economic penalties and trade disruptions.

The key requirements revolve around ensuring lumber is free from pests and pathogens that could pose a threat in new environments. This involves rigorous inspection, treatment, and documentation processes to maintain international trade standards. Compliance with ISPM 15 is essential for ensuring safe and efficient trade flows.

Mandatory Requirements for Compliance

The mandatory requirements for lumber to comply with ISPM 15 are comprehensive and cover all stages, from pre-treatment to post-shipment documentation. These requirements are designed to mitigate the risk of introducing pests into new ecosystems effectively. The precise measures vary based on the type of lumber and its intended destination.

Certification Procedures

Certification of lumber as ISPM 15 compliant involves a series of steps to demonstrate adherence to the international standard. These procedures typically include a pre-shipment inspection to verify compliance with the relevant treatment and packaging requirements, documentation of the treatment process, and a verification by a recognized certification body. The process should be thoroughly documented to ensure traceability and facilitate dispute resolution.

Type-Specific Requirements

Different types of lumber have varying requirements. Softwood lumber, often used in construction, might necessitate different treatment protocols than hardwood lumber, which is frequently used in furniture manufacturing. The type of wood, its moisture content, and the intended destination all influence the specifics of the required treatment.

Key Requirements for ISPM 15 Lumber

| Requirement | Description | Example | Compliance Method |

|---|---|---|---|

| Pest-Free Condition | Lumber must be free of all regulated pests, including insects and other organisms, to prevent the introduction of invasive species. | Wood shavings and sawdust are removed from the lumber stack before export. | Thorough visual inspection and potential fumigation. |

| Treatment Methods | Specific treatment methods, such as heat treatment or fumigation, might be mandated based on the type of wood and destination. | Heat treatment for softwoods to a specific temperature for a set duration. | Documented treatment process by a certified applicator, including temperature logs and operator signatures. |

| Packaging Requirements | Appropriate packaging is essential to prevent pests from escaping and ensure the treatment’s efficacy during transit. | Hermetically sealed packaging for fumigation to prevent gas escape. | Using certified packaging materials and methods to prevent damage during transport and maintaining airtightness. |

| Documentation | Comprehensive documentation is critical for traceability and compliance verification. | Certified treatment certificates, including the date, type of treatment, and inspector’s signature. | Detailed logs of all inspection and treatment procedures and maintaining a chain of custody. |

Documentation and Certification

Proper documentation is critical for ensuring ISPM 15 compliance and facilitating smooth international lumber trade. Accurate records demonstrate adherence to the standard, mitigating potential delays or rejection at customs. Thorough documentation not only supports legal requirements but also builds trust and credibility with international partners.

Necessary Documentation for ISPM 15 Lumber

Comprehensive documentation is essential for verifying compliance with ISPM 15 standards. The following table Artikels the key documents required:

| Document Type | Description | Purpose | Example |

|---|---|---|---|

| Phytosanitary Certificate | Official document issued by a competent authority in the exporting country. | Confirm that the lumber has been treated and inspected according to ISPM 15 standards. | “Phytosanitary Certificate – Export of Treated Lumber” issued by the USDA. |

| Export Declaration | Document detailing the shipment’s details, including quantity, destination, and treatment method. | Provides crucial information about the shipment for customs and tracking purposes. | “Export Declaration Form for Treated Lumber” |

| Treatment Certificate | Proof of the pest treatment applied to the lumber. | Demonstrates the effectiveness of the treatment in eradicating harmful pests. | “Treatment Certificate for Fumigation of Lumber” from a certified fumigation facility. |

| Pest-Free Certification | Document confirming that the lumber is free of quarantine pests. | Assures the importing country that the lumber poses no threat to their ecosystems. | “Pest-Free Certification – Pine Lumber” issued by a qualified inspection agency. |

ISPM 15 Certification Process

The ISPM 15 certification process involves several steps. Exporters must obtain the necessary documentation, including a phytosanitary certificate, from a designated authority. The documentation should demonstrate that the lumber meets all requirements of ISPM 15, including the specific treatment method and its efficacy. This process, while varying slightly depending on the country, generally involves 1) Treatment of lumber, 2) Inspection and certification by a qualified entity, 3and ) Issuance of the necessary phytosanitary certificates. This entire process should be well-documented and transparent.

Importance of Accurate Documentation in International Trade

Accurate documentation is paramount in international trade, particularly for lumber exports. Incorrect or incomplete documentation can lead to significant delays, rejection at customs, and potential financial losses. Furthermore, inaccurate documentation can damage the exporter’s reputation and hinder future trade relationships. Maintaining accurate records of treatment, inspections, and certificates ensures smooth transactions and upholds the integrity of the international trade system. This is crucial for protecting both the exporting and importing countries from potential pest infestations.

Typical Documentation for Exporting ISPM 15 Compliant Lumber

The following table highlights the common documents required for exporting ISPM 15-compliant lumber:

| Document Name | Description | Purpose | Format |

|---|---|---|---|

| Commercial Invoice | Detailed list of the lumber, including quantity, description, and value. | Provides crucial commercial information for customs clearance. | Standard commercial invoice format. |

| Packing List | Description of the lumber’s packaging and contents. | Helps in accurate inventory management and verification of the shipment. | Standard packing list format. |

| Bill of Lading | Document evidencing the contract of carriage for the shipment. | Provides evidence of the transportation of goods. | Standard bill of lading format. |

| Certificate of Origin | Proof of the lumber’s origin. | Provides proof of the origin for import duties and compliance purposes. | Standard certificate of origin format. |

Impact on Trade and Logistics

ISPM 15 significantly impacts international lumber trade, demanding adjustments in both export procedures and logistical frameworks. The standard’s implementation affects not only the movement of lumber but also the overall efficiency and cost structure of international commerce. This section will explore the effects of ISPM 15 on trade and logistics, including challenges and opportunities for compliance.

ISPM 15 compliance is essential for seamless international lumber trade. Non-compliance can lead to delays, increased costs, and even the rejection of shipments, impacting both exporters and importers. Understanding the specific logistics implications and potential cost variations associated with ISPM 15 compliance is crucial for maintaining competitiveness in the global lumber market.

Impact on International Trade

ISPM 15’s implementation has led to a noticeable shift in international trade practices for lumber. Exporters must now adhere to strict phytosanitary regulations to prevent the spread of pests and diseases. This results in a higher degree of scrutiny and increased documentation requirements during the export process.

Challenges Associated with Compliance

Meeting ISPM 15 requirements presents certain challenges for lumber exporters. These include the need for specialized treatment procedures, the costs associated with obtaining certification, and the potential for delays in the shipping process due to inspections and compliance checks. Furthermore, ensuring consistency in treatment across various batches of lumber can be complex and time-consuming. Effective communication and coordination between exporters, treatment facilities, and customs authorities are critical for smooth compliance.

Opportunities Associated with Compliance

Despite the challenges, ISPM 15 compliance presents opportunities. Meeting the standard enhances the trustworthiness and reliability of lumber exports, potentially opening up new markets and increasing export volumes. The certification process, while initially costly, establishes a higher quality standard, differentiating compliant lumber from non-compliant alternatives. This can lead to premium pricing and increased customer confidence in the product.

Logistics Implications for Moving ISPM 15 Compliant Lumber

The logistics of moving ISPM 15-compliant lumber differ significantly from those of non-compliant lumber. Crucially, compliant lumber requires specific treatment and certification, leading to additional handling and processing steps. This often involves coordinating with specialized treatment facilities and securing the necessary documentation. Transport routes and timelines might also need to be adjusted to accommodate the extra procedures.

Comparison of Logistical Processes

The logistical processes for ISPM 15-compliant and non-compliant lumber differ significantly. Non-compliant lumber may face delays due to inspection and quarantine procedures at the destination, potentially leading to costly demurrage fees. Compliant lumber, on the other hand, enjoys smoother transit and a reduced risk of rejection, streamlining the import and export process. The difference lies in the mandatory phytosanitary treatment, certification, and documentation associated with ISPM 15 compliance.

Potential Cost Increases/Reductions Associated with ISPM 15 Compliance

| Cost Factor | Description | Example | Impact |

|—|—|—|—|

Enforcement and Penalties

Source: martview.com

ISPM 15 compliance is crucial for international trade. Effective enforcement mechanisms are essential to ensure that all parties adhere to the standard, thereby preventing the spread of pests and protecting global agriculture. Penalties for non-compliance act as deterrents and contribute to the overall effectiveness of the standard.

Enforcement of ISPM 15 relies on a combination of proactive measures and reactive responses. Proactive measures involve educating exporters and importers about the requirements and providing resources for compliance. Reactive measures address instances of non-compliance, ensuring accountability and upholding the integrity of the standard.

Mechanisms for Enforcement

Various mechanisms are employed to ensure ISPM 15 compliance. These include:

- Import/Export Inspection by Authorities: Import and export inspection agencies play a critical role. Inspectors at ports of entry verify that lumber shipments comply with ISPM 15 requirements. This involves checking documentation, packaging, and the lumber itself for signs of pest infestation or insufficient treatment. These inspections can be random or targeted, depending on risk assessments and specific trade concerns.

- Regulatory Cooperation: International collaboration is essential. Agreements and cooperation between countries enable coordinated efforts to enforce ISPM 15 across borders. This shared responsibility promotes consistency in application and prevents loopholes.

- Trade Dispute Resolution Mechanisms: International trade organizations and national dispute resolution mechanisms are available to handle conflicts related to ISPM 15 compliance. These systems provide frameworks for addressing disagreements regarding treatment or certification. A well-defined procedure for dispute resolution promotes fair practices and a stable trading environment.

Penalties for Non-Compliance

Non-compliance with ISPM 15 can result in penalties. The severity of the penalty is often linked to the nature and extent of the violation. A system of escalating penalties can incentivize businesses to adhere to the standard.

| Violation | Description | Severity | Remedy |

|---|---|---|---|

| Incomplete or inaccurate documentation | Failure to provide proper phytosanitary certificates or other required paperwork. | Minor | Correction of documentation and resubmission. |

| Inadequate treatment of lumber | Failure to apply the correct level of fumigation or other treatment as specified in ISPM 15. | Moderate | Retreatment of the lumber and/or possible fines. |

| Uncertified or improperly certified lumber | Shipment of lumber without the required certification or with fraudulent documentation. | Severe | Possible fines, seizure of the shipment, and trade restrictions. |

| Shipment of infested lumber | Discovery of pests or evidence of infestation in the lumber. | Severe | Seizure of the shipment, quarantine, and potential penalties for the exporter and/or importer. |

Roles of Organizations in Enforcement

Various organizations play critical roles in enforcing ISPM 15 compliance. These include national plant protection organizations, port authorities, and international organizations involved in trade.

Pest Risk Management

Protecting lumber from pests is crucial for international trade and preventing economic losses. Infestations can damage goods, cause significant delays in shipping, and lead to the rejection of shipments. ISPM 15 plays a vital role in mitigating these risks.

Effective pest risk management is fundamental to ensuring the quality and safety of lumber products. A robust system encompassing prevention, detection, and treatment is essential. This ensures the continued flow of trade while minimizing the potential for harmful pests to spread.

Rationale for Pest Risk Management

Pest infestations in lumber can cause extensive damage, leading to significant economic losses for producers and consumers. The introduction of invasive species can devastate local ecosystems and impact biodiversity. Controlling pests is vital for preserving both the value of lumber and the environment.

Role of ISPM 15 in Preventing Pest Spread

ISPM 15 mandates specific treatments and procedures for lumber intended for international trade. The standardized approach minimizes the risk of introducing or spreading pests to new regions. The comprehensive guidelines, detailed in the standard, significantly enhance the safety and security of global trade.

Pest Management Methods for Lumber

A range of methods are employed for pest management in lumber. These include fumigation, heat treatment, and the use of insecticides. The appropriate method is selected based on the type of lumber, the target pest, and the specific requirements of the importing country.

Preventing Infestation During Manufacturing

Strict adherence to hygiene practices during lumber manufacturing is paramount. Regular cleaning and sanitation procedures are essential to minimize the risk of pest infestation. The use of pest-resistant materials and the implementation of effective pest control strategies during production are crucial steps in preventing problems.

Preventing Infestation During Storage

Proper storage conditions are critical to preventing pest infestation. Maintaining appropriate temperatures, humidity levels, and ventilation can significantly reduce the risk of pest proliferation. Regular inspections and prompt treatment of any identified infestations are vital to prevent the spread. Pest-proof containers and protective coverings are also crucial for maintaining the quality of stored lumber.

Preventing Infestation During Transport

Safe transport practices are essential for preventing pest infestation during transit. Packages must be sealed and inspected for pests. The use of appropriate packaging materials and secure transport containers further reduces the risk of infestation. Regular inspections during transit and adherence to specific regulations can help ensure the safe delivery of the lumber.

Specific Procedures for Pest Prevention

- Pre-shipment Inspection: Thorough inspection of lumber before shipment is essential. Inspectors should identify and document any signs of pest activity or damage. This proactive measure helps prevent the export of infested material.

- Treatment: Treatment methods should align with ISPM 15 requirements. These methods can include fumigation, heat treatment, or the application of insecticides. Strict adherence to the prescribed procedures is vital.

- Packaging: Packaging materials must be robust and pest-resistant. Proper sealing and protection of lumber during transit is critical to prevent infestations. The selection of suitable packaging is a significant factor in preventing infestation.

- Documentation: Accurate and detailed documentation of all treatment and inspection procedures is required. This ensures traceability and facilitates effective communication between stakeholders throughout the supply chain.

Practical Examples of ISPM 15 Compliance

Source: lesprom.com

ISPM 15, the International Standard for Phytosanitary Measures for wood packaging material, is crucial for preventing the spread of wood-borne pests during international trade. Implementing ISPM 15 effectively requires a comprehensive understanding of its requirements, including the proper treatment of lumber and the documentation needed to ensure compliance. This section offers practical examples demonstrating how manufacturers achieve ISPM 15 compliance, highlighting successful strategies and the steps involved in preparing and certifying lumber for export.

Examples of Lumber Products Complying with ISPM 15

Lumber products complying with ISPM 15 are treated or certified to prevent the introduction of harmful pests. For instance, kiln-dried lumber treated with heat or chemicals to eliminate pests is a common example. Another example includes lumber certified by a recognized organization, such as a national forestry certification body, that assures the material has undergone the necessary processes to meet ISPM 15 requirements. Specific types of lumber, such as pressure-treated lumber, are inherently more likely to meet the standard due to the inherent treatment processes already employed.

Illustrative Examples of Successful ISPM 15 Compliance Procedures

Manufacturers successfully implementing ISPM 15 often use a combination of strategies. A key element is a robust quality control system, encompassing rigorous inspections at various stages of production. This might involve visual inspections of lumber for signs of pest damage or infestation, nd verification of treatment methods, and documentation. Another important aspect is the use of certified suppliers and contractors. This ensures that the entire supply chain adheres to the required protocols. A well-documented record-keeping system is essential for tracing the lumber’s journey from origin to destination, including treatment procedures, dates, and any relevant certifications.

Process of Preparing Lumber for Export in Compliance with ISPM 15

The process begins with pre-treatment inspections to assess the lumber for any signs of pest infestation. After inspection, appropriate treatments are applied, adhering to specific guidelines. This may include heat treatment, fumigation, or chemical treatment, as determined by the type of lumber and the destination country’s requirements. Documentation of all treatment procedures, including the date, method, and responsible personnel, is crucial. Importantly, the lumber is then carefully packaged and labeled, clearly indicating its ISPM 15 compliance status and any relevant certifications.

Detailed Descriptions of Inspecting and Certifying ISPM 15 Compliant Lumber

Inspection involves a thorough visual assessment for signs of infestation, damage, or any non-conformities with the prescribed treatment. The inspector must also confirm that the appropriate treatment method has been applied and that the treatment records are complete and accurate. Certification, often handled by accredited organizations, validates the entire process, from pre-treatment inspections to final packaging and labeling. The certificate acts as proof that the lumber meets ISPM 15 standards and is suitable for export. Certificates typically include details about the lumber, its treatment, and the certifying organization. A well-structured certification process involves verifying the lumber’s origin, its compliance with the ISPM 15 requirements, and the authenticity of the documents.

Summary of ISPM 15 Compliance for Lumber

A summary of the key aspects of ISPM 15 compliance for lumber emphasizes the importance of preventive measures in the lumber supply chain. This includes careful inspection, rigorous treatment procedures, and accurate documentation. Effective implementation of ISPM 15 ensures the lumber meets international standards, minimizing the risk of introducing pests into new environments. A robust compliance system includes rigorous inspection procedures and verification of all treatment steps. Documentation is crucial in tracing the lumber’s history and confirming its ISPM 15 compliance.

Summary

In conclusion, adhering to ISPM 15 lumber regulations is essential for seamless international trade. The guidelines in this document provide a comprehensive understanding of the requirements, facilitating informed decision-making and ensuring smooth export procedures. Navigating these standards can present logistical challenges, but a thorough understanding of the regulations can minimize potential issues and maximize opportunities in the global market.